介绍

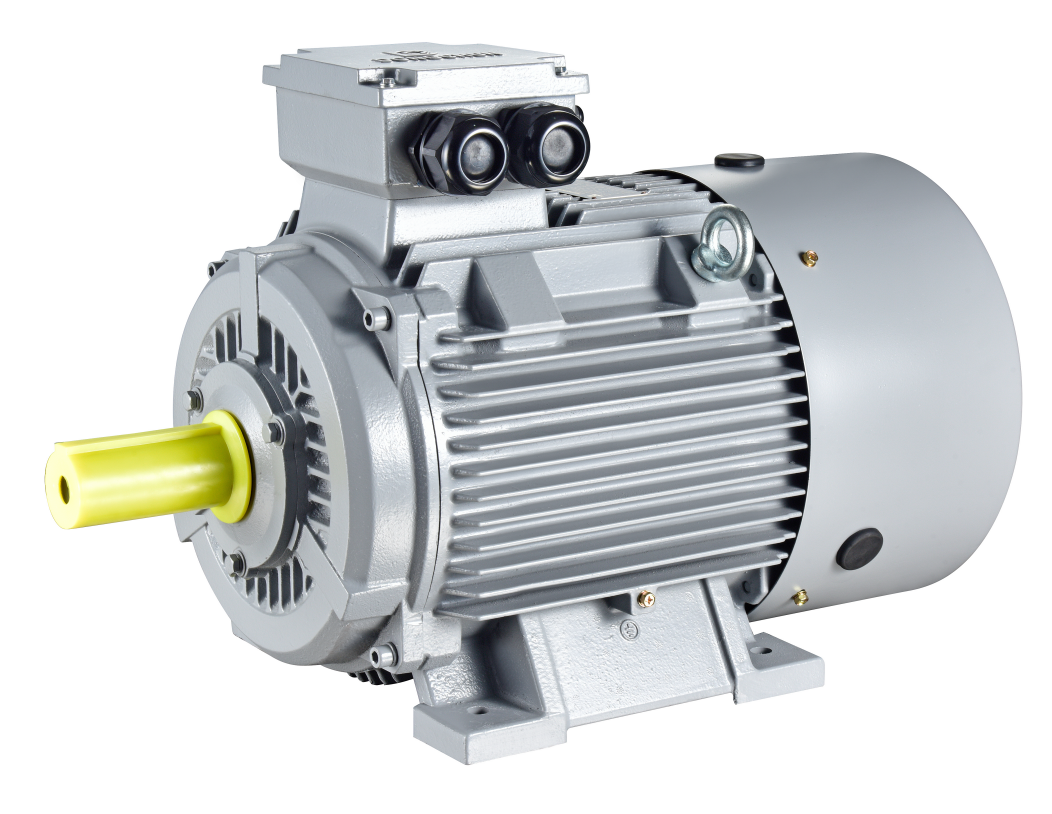

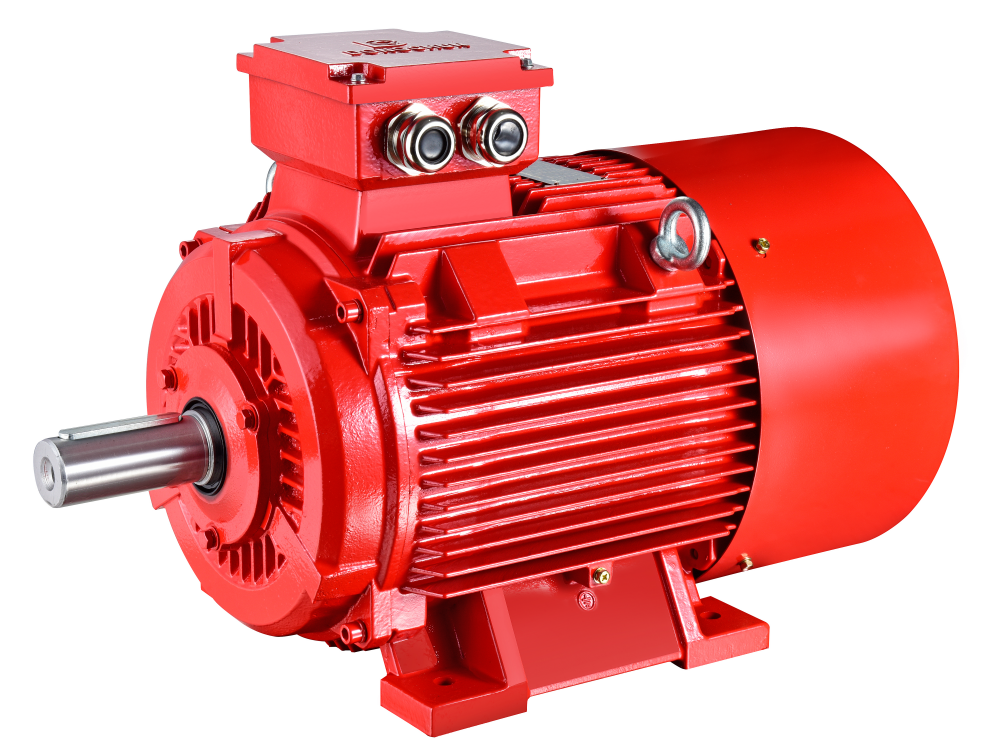

In the industrial field, small and medium-sized three-phase asynchronous motors are currently the most widely used motor products.

Different induction motors have different applications, with the continuous development of electric motor manufacturing technology and research on the working principle of industrial motors.

There are also many new types of electric motors, including rare earth permanent magnet motors, switched reluctance motors, synchronous reluctance motors, etc.

A brief introduction to the various types of electric motors

中小型的三相异步电动机目前是用于工业应用的最广泛使用的电动机产品。

三相异步电动机是一种交流电动机,也称为感应电动机。

它具有一系列优势,例如简单结构,易于制造,鲁棒性,易于维护,低成本和低价。

因此,它被广泛用于工业,农业,国防,航空航天,科学研究,建筑,运输和人们的日常生活中。

它具有低功率因数,并且在其应用方面有些限制。

1。三相异步电动机的结构

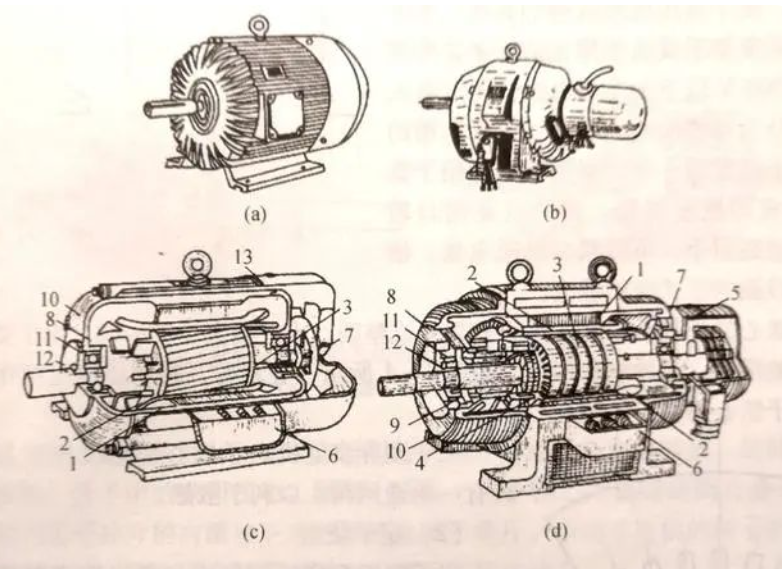

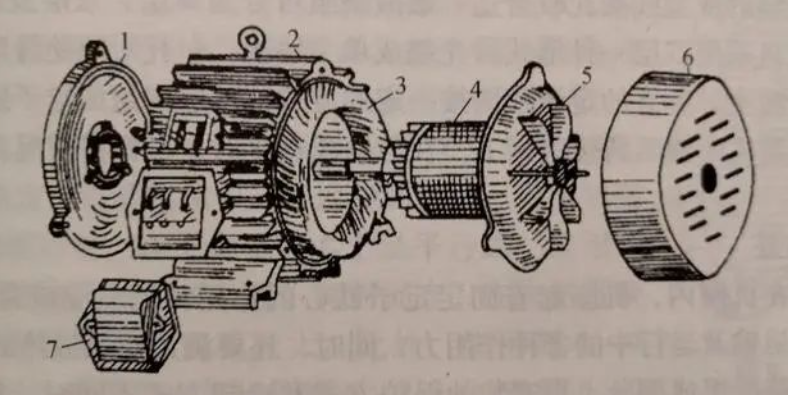

准备三相感应电动机以拆卸,并从外部看一下其结构。

下图显示了三相感应电动机的轮廓和截面视图。

从电动机的外部,您可以看到风扇盖,风扇,左侧和右侧盖,铭牌和终端盒。

打开终端盒,您可以看到端子柱和导线线。

卸下风扇盖,风扇和端盖,拉出转子,您可以看到电动机内部的定子芯,转子芯,轴,轴承和其他部分。

定子芯被加载在外壳中,转子芯安装在电机轴上。

定子芯有线圈(绕组),并且转子芯在其中带有一个笼子形的铝制条。

Winding linear rotor iron core with rotor windings.

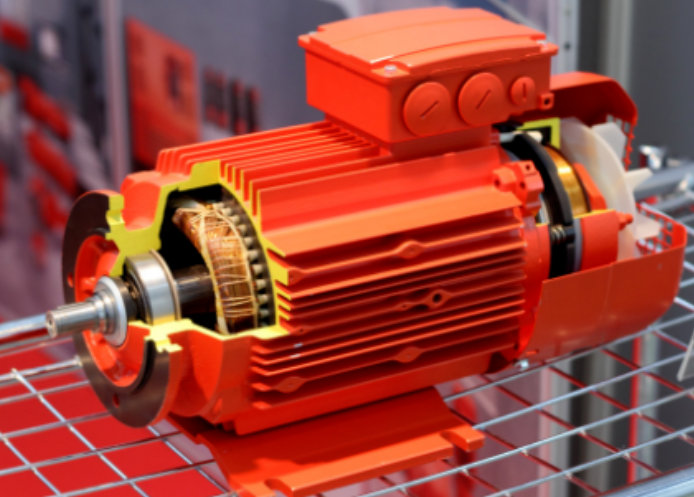

As can be seen, the basic structure of the squirrel cage electrical motors consists of a fixed and immovable part, a rotor and other parts, as shown in the figure below:

The rare earth permanent magnet motor

It is a new type of permanent magnet motor that emerged in the early 1970s.

The magnetic properties of rare-earth permanent magnet materials are so excellent that they can be magnetised to create a strong permanent magnetic field without the need for additional energy.

The rare earth permanent magnet motor is not only highly efficient, but also has a simple structure, reliable operation and is small in size and light in weight.

他们可以实现高性能(例如,高效率,高速,高响应),无法与传统的电动电机相匹配,也可以将其制成可以满足特定操作要求的特殊电动机。

高性能稀土永久磁铁电动机是许多新技术和高科技行业的基础。

结合电力电子设备和微电控制技术,它可以生产具有出色性能的各种机甲产品,例如CNC机床,加工中心,灵活的生产线,机器人,电动汽车,高性能的家用电器,计算机,计算机等。

随着永久磁铁同步电动机的发展,高效率的永久磁铁同步电动机用于高温,高真空,电动汽车,内部逆变器,低速下的高扭矩和自动启动,逐渐进入特定的应用。

由于电动机对不同操作条件的特定性能要求,永久磁铁电动机的一般开发逐渐显示出一些特定的特征。

高功率和超高速度作为永久磁铁电动机的发展方向

为了提高感应电动机的额定功率,但必须大大提高电气交流电动机的速度。

Rare earth permanent magnet motors do not require excitation windings, have a relatively simple structure, have no heat source in the magnetic field section, do not require cooling devices, have high coercivity of the material.

It can take on larger values for the air gap length, thus making it possible to increase the speed considerably.

High performance direction

Modern equipment to the motor industry put forward a variety of high-performance requirements.

Such as military equipment requirements to provide a variety of high-performance signal motor, mobile power station, automation equipment with servo systems and such motors, aerospace with high-performance, high reliability permanent magnet motor, chemical fiber equipment with high speed regulation accuracy frequency synchronous motor, CNC machine tools, machining centres, robots with high speed than rare earth permanent magnet servo motor, computer with high-precision swing motor and spindle motor, etc., to the direction of special industrial motors development.

Development in the direction of lightness

航空航天产品,电动汽车,CNC机床,计算机,视听产品,医疗设备,便携式光学机电一体式产品等都提出了针对小鼠笼子感应电动机的严格要求,尺寸较小,重量较小。

永久磁铁同步电动机已被开发并应用于升降技术,其尺寸较小,节能,良好的控制性能,易于制作低速直接驱动,消除齿轮降低设备以及通过频率变化的速度调节。

开关不情愿驱动(SRD)

It is the latest generation of stepless speed control system developed after the frequency control system and brushless DC motor speed control system. It is an integrated high technology of light, electric machine and electricity integrating modern micro-electronics, digital technology, power electronics, infrared photoelectric technology and modern electromagnetic theory, design and production technology.

It has a speed control system both DC, AC two types of speed control system advantages.

Britain, the United States and other economically developed countries on the switch reluctance motor speed control system research started earlier, and has achieved significant results, product power level from a few w to hundreds of kw, widely used in household appliances, aviation, aerospace, electronics, electric machines and electric vehicles and other fields.

The convex poles of the stator and rotor of the switched reluctance motor are laminated from common silicon steel sheets, a process that minimises eddy current and hysteresis losses in the motor.

There are no windings or permanent magnets on the rotor poles, no commutators, no slip rings, etc. The stator poles are wound with concentrated windings, and the two radially opposite windings are connected in series to form one phase.

The switched reluctance motor is electrical motors that generates torque by using uneven rotor reluctance, also known as a reactive synchronous motor, whose structure and working principle are very different from those of traditional synchronous AC motors and DC motors.

It does not rely on the interaction of the magnetic fields generated by the stator and rotor winding currents to produce torque, but on the "principle of minimum reluctance" to produce torque.

This means that "the magnetic flux always closes along the path of least resistance, thus creating a magnetic pull, which in turn creates an electromagnetic torque of a magnetoresistive nature" and "the magnetic lines of force have the nature of trying to shorten the path of the flux in order to reduce the resistance and increase the permeability".

Magneto-resistive synchronous motor

它是从相同的笼型异步电动机演变而来的,其转子具有笼子型铸造铝绕组电阻,但具有反应插槽对应于定子电线杆的数量(只有角色的凸段部分,没有激发绕组和永久磁体),用于产生不耐力同步扭矩。

耐磁性同步电动机分为单相电动机,单相电容器运行,单相电容器启动和单相双值电容器类型。

应用领域:不情愿同步电动机主要用于工业和农业生产,运输,国防,商业和家用电器,医疗和电气设备等。

SWOT analysis of the above four types of electric motors

1)中小型三相异步电机

Advantages: high reliability, low cost, high technological maturity, high market share.

Disadvantages: low efficiency of ordinary motors, low technical threshold, fierce competition, insufficient technical innovation.

Opportunities: In places with high requirements for reliability of working conditions, ordinary working conditions can be met, and the promotion of high-efficiency industrial motor is the focus of energy-saving efforts.

Threats: The market for rare earth permanent magnets is expanding, especially in the market for high efficiency motors.

(2) Rare-earth permanent magnet motors

Advantage: not only high efficiency, but also simple structure, reliable operation, but also small size and light weight.

Disadvantages: Cost is 30% higher than asynchronous motors, and demagnetisation will occur at high temperatures for a long time.

Opportunities: oil fields, textile and chemical fibre industry, ceramic and glass industry and fans and pumps with long annual running time.

Market share gradually expanding.

Threats: cannot be used in places with too much power, mainly because the cost is too high and the production process is difficult.

(3) Switched reluctance motors

Advantages: simple motor structure, low cost, can be used for high speed operation. Simple and reliable power circuit, large starting torque, low starting current, suitable for frequent starting and stopping, forward and reverse conversion operation, good speed regulation performance.

缺点:在低速下,高噪声和明显的扭矩搏动。它需要与控制器一起使用,两者的成本很高。当前功率范围为8kW-400kW,仅适用于特殊应用。在一般目的区域中,与AC异步和直流逆变器速度控制系统相比的优势并不明显。

机会:电动汽车,纺织工业,可乐行业,家用电器行业,用于可以利用其优势的地区,即需要高起始扭矩,高速要求,炎热潮湿的环境以及频繁的随机旋转的区域。

威胁:高噪声水平的问题很难克服,并且开发是有限的。

(4)同步不情愿电动机

Advantages: Compared with permanent magnet synchronous motors, the cost of the motor is greatly reduced under the same power conditions, while the range of use of the motor is broadened and the reliability of the motor operation is improved. Due to the simple structure, the rotor does not have electromagnetic losses and can avoid the disadvantages of switching reluctance motors such as high noise and significant torque pulsation at low speeds.

Disadvantages: low power factor and low output compared to asynchronous motors of the same size.

Opportunities: Industrial and agricultural production, transport, defence, commercial and domestic appliances, medical and electrical equipment, etc.

Threats: At the research stage.

The current research is on fractional horsepower motors, which have little place in AC systems.

Comparative analysis of motor products

| Projects | Small and medium-sized three-phase asynchronous motors | Rare earth permanent magnet motors | Switched reluctance motors | Synchronous reluctance motors |

| Cost | Low | Medium | 高的 | Medium |

| Reliability | 高的 | Low | Low | Low |

| Technical maturity | Very mature | Fairly mature | Fair | Immature |

| Market share | Extremely large | less | Less | None |

| Efficiency | average | 高的 | Fair | Fair |

| Copper density | 高的 | Lower | Lower | Lower |

| Simple structure | poor | 好的 | Fair | 好的 |

| Size and quality | Large, heavy | Small, Light | Small, Light | Small, Light |

| Noise | Low | Low | 高的 | Low |

From a comparative analysis of the various competitive products on several levels, the small and medium-sized three-phase asynchronous motor is still the most technically mature product with the largest market share.

However, in the future, we need to further optimise the process, improve the technology and make further improvements in terms of efficiency and compactness in order to maintain a high level of competitiveness.

Welcome to contact Dongchun motor to get a free quote of three-phase asynchronous motor as follows;

请向电动机制造商检查如下;

获取东春汽车免费报价

如果有什么意见,欢迎给我留言。